Scopewire trade fair offer:

LkSG risk analysis free of charge

LkSG Supplier Risk Analysis

4 weeks free

We are committed to ensuring that your company can effortlessly meet the requirements of the LkSG. The quality of your supplier master data is crucial.

Supplier risk analysis is at the heart of every LkSG project. It enables you to identify and assess potential risks in your supply chain. Our platform gives you the tools to do this in an automated, efficient and reliable manner.

Contact us today to find out more about our solutions or start your free test run right away. Scopewire Data GmbH - your partner for your successful LkSG project.

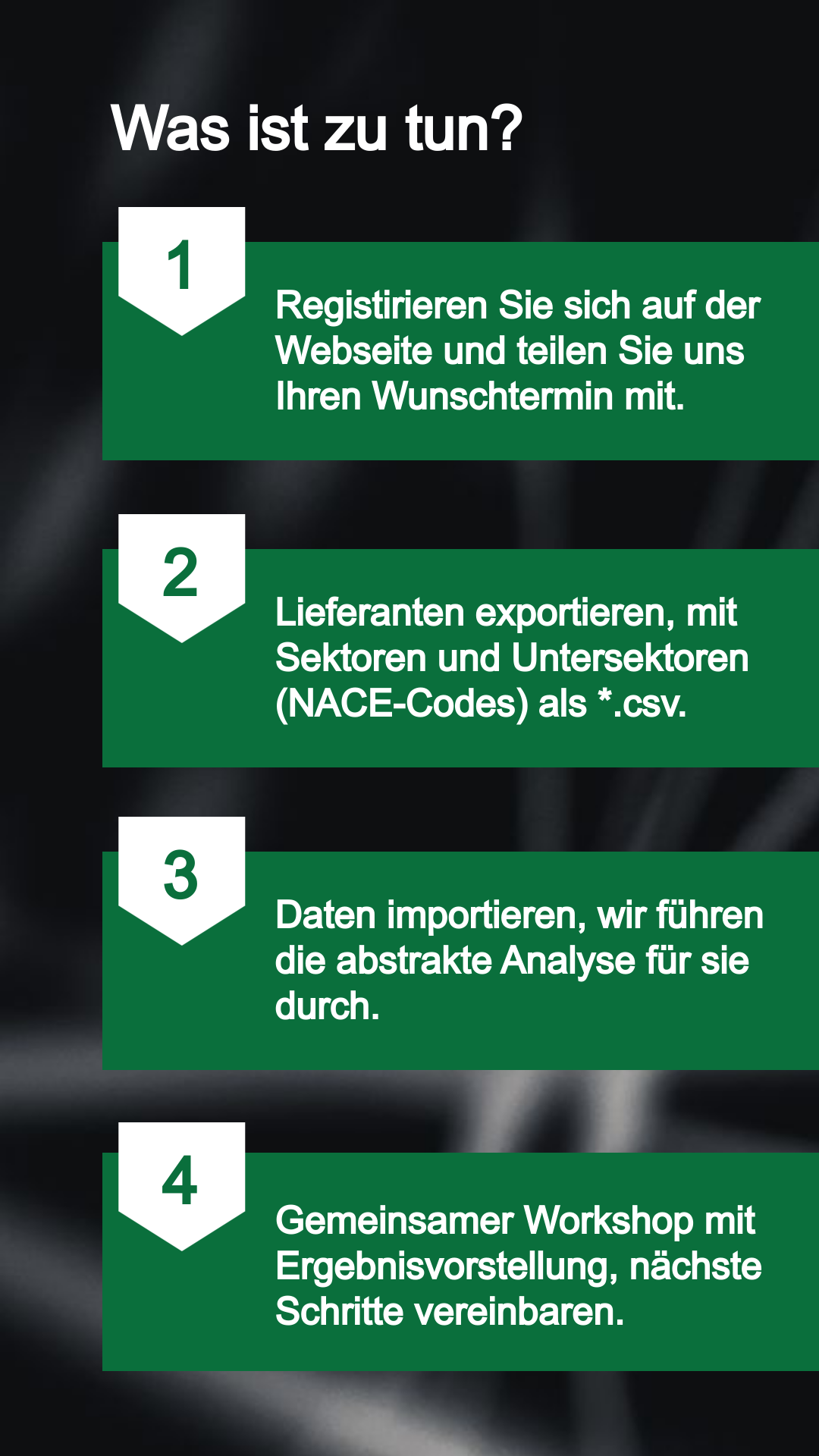

Your path to a free risk analysis:

Challenges of supplier risk analysis (detailed)

Data quality

Ensuring adequate data quality for supplier data is a major challenge, particularly in the context of meeting the requirements of the Supply Chain Due Diligence Act. In order to be able to carry out a comprehensive risk analysis, a large amount of information about suppliers is required, which is often complex and multi-layered.

An essential part of this information is the assignment of suppliers to specific sectors and subsectors or even to NACE codes in order to better assess risks and potential impacts on the supply chain. However, collecting and updating this data can be a major challenge, especially when suppliers operate in different industries or their fields of activity change.

In order to efficiently achieve the required data quality, we are happy to support you with tailor-made solution strategies. Our consultants offer you practical approaches to achieve your goal with calculable effort. This can include, among other things, the implementation of automated data validation systems, the use of databases with industry-specific information or the involvement of suppliers in the data collection and updating process.

Through a holistic approach and the targeted support of our consultants, you can ensure that your supplier data is of high quality and meets the requirements of the Supply Chain Due Diligence Act.

Data export and import

Data export and import of supplier data from ERP systems presents a number of challenges that can impact the quality and consistency of the data. A commonly used method for exporting is the CSV format, but this can have various potential sources of error.

Some of the challenges typically encountered when exporting and importing supplier data include:

-

Date formats: Different ERP systems may use different date formats, which can lead to inconsistencies during export and import. This can lead to misinterpretation or incorrect mapping of data.

-

Postal codes: Postal code formatting may vary by country, which may cause problems when importing into other systems, especially if they are not recognized or converted correctly.

-

Language settings: ERP systems can operate in different language versions, which can lead to inconsistencies in data transfer, especially if the language settings are not configured correctly.

-

Different ERP systems: In large corporate structures, different subsidiaries or departments may use different ERP systems. This leads to additional complications when exporting and importing supplier data, as they may be incompatible or use different data formats.

To meet these challenges and ensure that a legally compliant supplier analysis can be carried out, a comprehensive assessment of the entire supplier base is required, including all subsidiaries and shareholdings. Our data specialists are specialized in overcoming these challenges and will be happy to help you extract, transform and load the data from the various ERP systems to ensure a consistent and reliable data basis for your supplier analysis.

Your result

After completing the free risk analysis with the Scopewire Supply Chain cloud solution, you will receive a detailed overview of your suppliers' risk assessment. This analysis is based on a pre-qualified risk scoring value, which is determined based on a variety of factors such as financial stability, compliance with legal regulations, supplier history and other relevant criteria.

The result of the risk analysis is clearly presented in an Excel format that allows you to easily process and analyze it. In the Excel file you will find a summary of all assessed suppliers and their respective risk scoring values.

The benefit of this free risk analysis lies in the speed and efficiency with which you gain important insights into your suppliers' risks. The clear structuring of the data allows you to react quickly and, if necessary, take measures to reduce risk or diversify your supply chain. Scopewire Supply Chain thus enables you to proactively manage your supplier risk and strengthen your supply chain to minimize potential disruptions or failures.

Our experienced consultants will be happy to assist you with the interpretation of the results, supplier forensics and the entire process design with regard to the optimal implementation of the Supply Chain Due Diligence Act (LkSG) in your company. Our experts have in-depth know-how in supplier evaluation and analysis as well as in the implementation of risk reduction and compliance measures.

With their technical expertise, they support you in correctly interpreting the results of the risk analysis and deriving suitable recommendations for action. They can also help you develop and optimize processes and guidelines in order to implement the requirements of the LkSG efficiently and effectively.

Our goal is to offer you comprehensive support so that you can make your supply chain robust and compliant with the law. From analysis to implementation, we are at your side as a reliable partner to minimize your supplier risks and prepare your company for future challenges.